Modern Cabinetmaking: Big Technology in a Small Town

By Suzanne VanGilder

Published by FDMC/ Woodworking Network

Nestled amongst the forests, farmland and lakes of central Minnesota is the tiny town of Osage, population 323. Visitors will find the expected: timber frame cabins, bait shops, friendly people with hotdish- but Osage is also home to something rather unexpected- a custom cabinetmaking operation complete with state-of-the-art automated finishing and game-changing production technology.

“My vision has always been to be a large manufacturing company,” said Steve Pachel, owner and CEO of SWI Interiors. “But I am a born and raised farm boy. After school, I left the farm for a while and did some work re-finishing furniture and making cabinets. But I needed to be home. My folks had sold the dairy operation, and as much as I enjoy refinishing furniture, you can’t grow it big. That’s always been something about me, I like to grow. So in 1996 I started building cabinets in a tiny 400 ft.² shop in my grandfather’s barn. In 2007 I bought the old mill in Osage. Now we are at 36,000 ft.² with 50 employees, and we’ll put out 1250 units this year. I still don’t know where the end is. We’re just going to grow steady and profitable and see where it takes us.”

Don’t be fooled by the Little House on the Prairie setting, SWI Interiors is a prime example of a successful, modern cabinetmaker with an eye to the future.

Three fundamental – and interrelated- principles allow SWI Interiors to not only compete in the cutthroat market of cabinet manufacturing- but to grow:

- Providing turnkey service in addition to quality product.

- Investing in technology- both production and software.

- Building supplier and customer relationships.

The Turnkey Custom Cabinet

“We build custom cabinets and countertops, including a builder-grade line, a semi-custom line and a fully-custom line,” said Pachel. “Instead of trying to compete with the big guys, our vision is to provide turnkey solutions. We design, build, final measure, install and touch up all of our projects, making it easy for the trade.”

SWI Interiors sells through wholesalers, lumber yards, floor-to-ceiling design centers and directly to big builders. For 21-years Pachel has methodically expanded the turnkey cabinet approach, setting up designers, installers and field service representatives in new territories.

Currently SWI Interiors has an established presence in Fargo- Moorhead, Minneapolis- Saint Paul, Bismarck and Grand Forks, N.D, Sioux Falls, S.D., and is making in-roads into Montana.

“Another unique thing is we can produce virtually any cabinet, so we don’t really have a catalog. Instead we use KCD software customized to our methods.” said Pachel. “When we set up a new distributor, wholesaler or team member they get a key to our KCD Designer. They can design with any cabinet in our library, modify it to any size, add any finish. The software also works as a sales tool, generating high-resolution renderings and estimates.

Finalized designs are sent back to our shop in Osage, where they integrate directly into our manufacturing processes. We have the full KCD Commander, so if a change is made in the design, the software automatically adjusts other components- and carries the changes through cut lists and machine code. The software makes it easy for dealers to sell our product, and for us to produce for many different dealers. It’s allowed us to grow substantially.”

Internally SWI Interiors has a motto, “We are all about wood,” and indeed, with the exception of turnings and corbels sourced from Osborne Wood Products, SWI builds the entire cabinet. The vast majority of the door and drawer fronts produced are hardwood from Renneberg Hardwoods or routed and painted HDF from Roseburg Forest Products.

Within the custom line, finishes are essentially unlimited. For the semi-custom product, SWI Interiors stocks 196 stains and 56 paints. From that coating repertoire the company is able to match any specified color. High-quality hardware from Blum or Rev-A-Shelf completes the cabinet.

Robust Technology

Looking at SWI Interior’s shop, it’s hard to believe that Steve Pachel wasn’t always a tech guy.

Part of what made him embrace technology was something most cabinetmakers can relate to- difficulty finding good employees. “Growing up on the farm, I knew what it was to work. Starting out I assumed everyone did, and I could just hire people for jobs. I quickly learned that is not the case,” said Pachel. “As I struggled with that I started adding automation, then hiring and training good operators for careers. It works.”

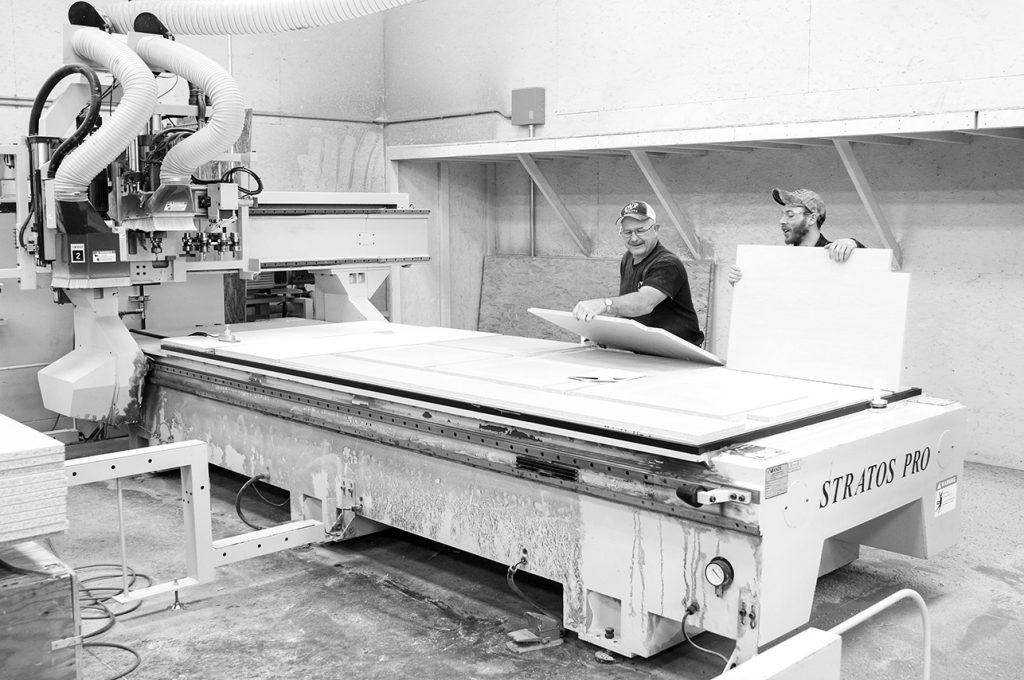

Two Anderson CNC routers, supported by Schmalz vacuum lifts, are the work horses of SWI Interior’s cabinet production. There is a door machining center, and Weinig Opticut cross-cut saws adding flexibility into the process. “We get the designs either through email or DropBox, proof them, and then it is literally screen to CNC. The KCD Software turns the designs into nested-based G-code to run the equipment,” said Pachel. “I see it every day, but when you stop and look at what we’ve built, it’s pretty cool.”

Parts are prepped with Timesavers orbital sanders before going to the company’s latest investment, a Superfici automated flat-line finishing system. Installed in 2017, the automated finishing system increases SWI Interior’s capacity, allowing the company to maintain its competitive speed-to-market while keeping pace with growth. At the same time, it creates opportunity to function as an OEM and grow new revenue streams.

Relationships Matter

“One thing I can tell you about SWI’s success,” said Pachel, “is without my employees, customers and vendor relationships, I’m nothing.”

Sometimes integrating new technology is challenging.

For SWI Interiors, getting the automated finishing line up and running took some effort. The system runs a two-part conversion varnish. Mixing is a delicate process, and in Minnesota’s climate with extremes of temperature and humidity, the formula requires constant adjustment. “We partner with Axalta for our coatings. Used to be Valspar wood-finishing, but nothing has changed with the product,” said Pachel. “They were here a lot when we added our flat-line, helping to get everything working right. They’re still here once a week making sure things run smoothly.”

Sometimes integrating new technology is easy.

“KCD was new when I started with them. We’ve watched them grow as we’ve grown,” said Pachel. “They’re great technology partners because they offer a lot of support and they’re also cabinetmakers. KCD gets it. Many times over the years we’ve asked them for different programs to help with different scenarios. Often when a new version comes out, the solutions they figured out for us are built-in to make the software better.”

Sometimes integrating new technology is a way to grow.

Whether it is adding custom-finishing capabilities to open up new revenue streams, or streamlining the design and production processes to open up new markets, SWI Interiors’ invests in innovations to help provide turnkey custom cabinets and build mutually-beneficial relationships.

“Our vision is to continue to expand as a hybrid custom cabinet manufacturer. So no matter where our product ends up, we still do the design, production, final measurements, installation, walk through and touch ups after every single job. There’s a lot of value in that to the trade.” said Pachel. “We have a lot to learn yet, and lots of potential to grow.”